Why Choosing the Right Roof Replacement Material Matters

Choosing the right material for a TPO roof replacement is one of the most important decisions you’ll make for your flat or low-slope roof. As Delaware’s trusted roofing experts, we’ve helped hundreds of property owners compare options like TPO, EPDM, and PVC to find the best value and longest-lasting solution. The right material protects your investment, reduces energy costs, and withstands Delaware’s coastal weather.

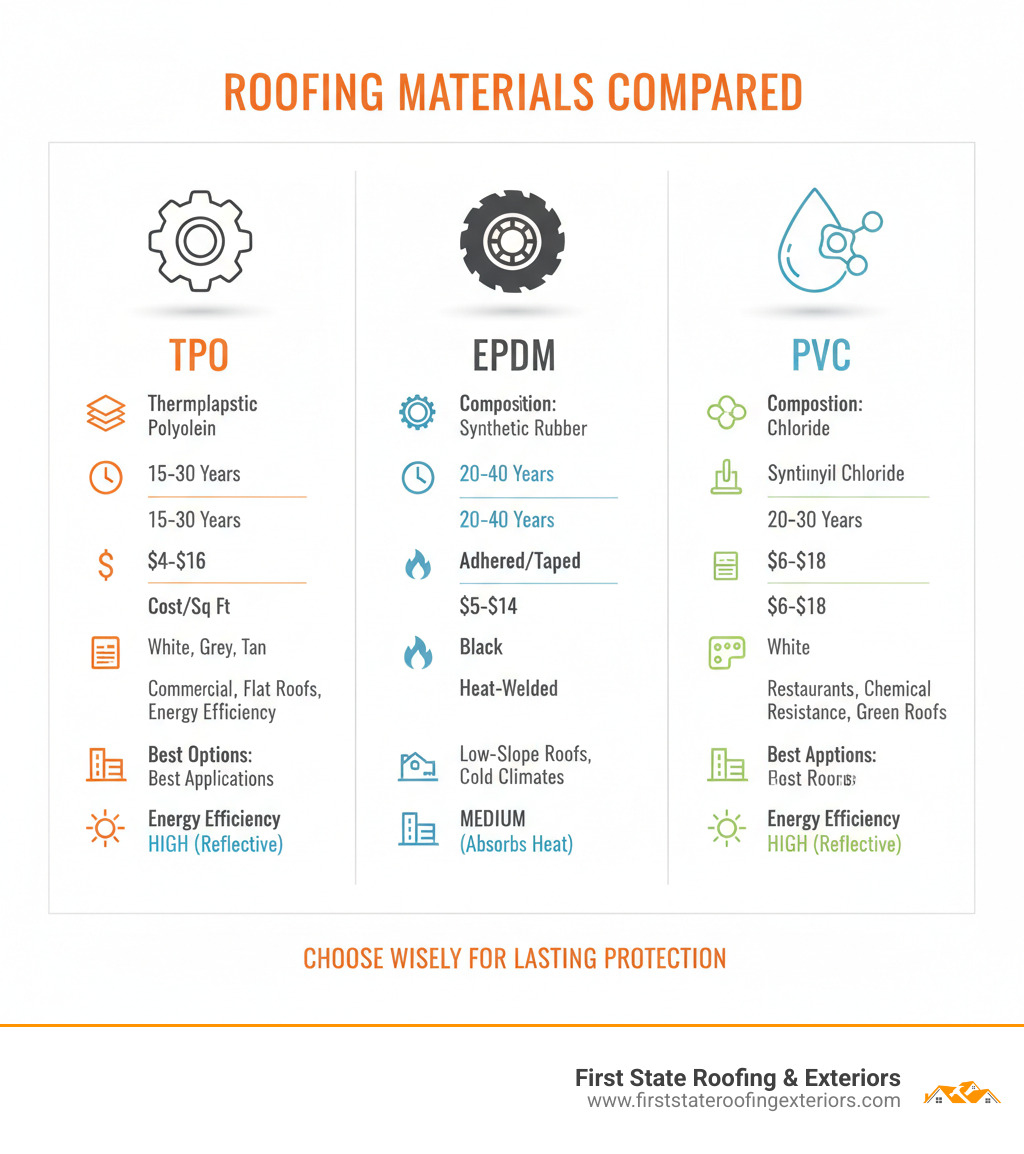

Here’s a quick overview of TPO (Thermoplastic Polyolefin):

- It is a white, heat-reflective single-ply membrane that typically lasts 15-30 years.

- Installation costs range from $4-$16 per square foot, depending on various factors.

- It offers strong heat-welded seams, excellent UV resistance, and energy savings.

- It’s best for commercial buildings and flat roofs where energy efficiency is a priority.

This guide breaks down everything you need to compare single-ply roofing options and choose the right system for your property. For expert guidance, call us at (302) 222-4065 to schedule a free inspection and receive a detailed estimate.

Understanding Single-Ply Roofing Materials

Single-ply membranes are the modern solution for flat and low-slope roofs, creating a continuous, watertight barrier without the weight of older built-up systems. These flexible sheets of rubber or plastic are ideal for commercial buildings, garages, and home additions across Delaware. The three most common options are TPO, EPDM, and PVC, each with distinct advantages.

What is TPO (Thermoplastic Polyolefin) Roofing?

TPO is a single-ply membrane made from a blend of polypropylene and ethylene-propylene rubber, reinforced with a polyester scrim for stability. Its key feature is its heat-welded seams, where hot air fuses the material together to create a monolithic bond that is stronger than the membrane itself. This process provides superior leak resistance. TPO’s standard white color reflects sunlight, significantly reducing cooling costs, and it offers excellent puncture resistance, making it a durable and energy-efficient choice.

What is EPDM (Ethylene Propylene Diene Monomer) Roofing?

Known as the “workhorse” of flat roofing, EPDM is a synthetic rubber membrane with a track record spanning over 60 years. It is exceptionally durable against extreme temperatures and hail. Unlike TPO, EPDM seams are sealed with adhesive tapes or liquid adhesives. While reliable when installed correctly, these seams can be a vulnerability over time. Its standard black color absorbs heat, which can increase cooling costs in Delaware’s climate, making it better suited for non-conditioned spaces like garages or storage facilities.

What is PVC (Polyvinyl Chloride) Roofing?

PVC is a premium plastic-based membrane known for its exceptional chemical resistance, making it the ideal choice for restaurants or industrial facilities exposed to grease, oils, and chemicals. Like TPO, PVC seams are heat-welded for a strong, watertight seal, and it comes in light, reflective colors for energy efficiency. The primary drawback is its cost, which is typically higher than TPO. However, for specialized applications requiring chemical resistance and longevity of over 25 years, PVC is a smart investment.

TPO vs. EPDM: A Head-to-Head Comparison for Your Roof Replacement

Choosing between TPO and EPDM is a common decision for property owners needing a flat roof solution. While both are reliable, their differences in performance, cost, and energy efficiency can significantly impact your property’s long-term value.

Performance, Durability, and Lifespan

- Lifespan: A properly installed TPO roof typically lasts 15-30 years, while EPDM often reaches 25-30 years. Longevity for both depends on installation quality, maintenance, and climate.

- Seam Integrity: This is the biggest difference. TPO’s heat-welded seams create a single, fused layer that is incredibly strong and leak-resistant. EPDM relies on adhesive seams, which, while effective, can be more prone to failure over time compared to welded seams.

- Durability: TPO offers superior puncture resistance, which is important for roofs with foot traffic or in areas with storm debris. TPO also has better chemical resistance to oils and grease than EPDM.

- UV Resistance: Both materials handle UV exposure well. However, TPO’s light color reflects UV rays, reducing heat absorption, while EPDM’s black surface absorbs it.

Cost Analysis and Return on Investment

For a TPO roof replacement, total installation costs generally run between $4 and $16 per square foot. This includes the membrane, insulation, fasteners, and labor. EPDM costs are often comparable upfront.

The real difference in ROI comes from long-term energy savings. TPO’s white, reflective surface acts as a “cool roof,” lowering the building’s temperature and reducing the load on your air conditioning system. This can lead to significant savings on utility bills over the roof’s lifespan, making TPO a more cost-effective investment in Delaware’s climate. For a detailed breakdown, see our Roof Replacement Cost Guide 2025.

Energy Efficiency and Environmental Impact

TPO’s primary environmental advantage is its energy efficiency. By reflecting solar radiation, it lowers cooling costs and helps reduce the urban heat island effect. Furthermore, TPO is a recyclable material at the end of its service life and is manufactured without harmful plasticizers.

EPDM’s black surface absorbs heat, which can increase cooling costs in warm climates. While durable, it does not offer the direct energy-saving benefits of a reflective TPO roof. For most Delaware properties, the energy savings from TPO provide a clear advantage.

The Complete TPO Roof Replacement Process

A professional TPO roof replacement is a systematic process that ensures decades of reliable performance. Understanding the steps helps you know what to expect from a quality installation.

Signs Your TPO Roof Needs Replacement

Look for these warning signs that indicate your roof is nearing the end of its life:

- Age: The roof is over 20 years old.

- Membrane Damage: Widespread cracking, brittleness, or multiple punctures.

- Seam Failure: Seams are separating, lifting, or showing gaps.

- Water Infiltration: Persistent leaks, water stains on ceilings, or bubbling on the roof surface.

- Ponding Water: Water that stands for more than 48 hours after rain, indicating drainage problems.

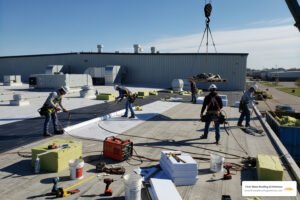

A Step-by-Step Guide to TPO Roof Replacement

- Inspection and Preparation: We thoroughly inspect the existing roof and deck, identifying any damage. The surface must be clean, dry, and smooth for the new system.

- Removal of Old Roofing (If Necessary): A full tear-off is required if you have two or more existing roof layers or if the underlying insulation is wet. This allows for a full inspection of the roof deck.

- Insulation Installation: New insulation boards (typically polyisocyanurate) are installed to meet energy codes, improve efficiency, and provide a smooth substrate for the membrane.

- Membrane Attachment: The TPO membrane is rolled out and secured. This can be done by mechanically fastening it with plates and screws, fully adhering it with adhesive, or holding it down with ballast (stones).

- Heat-Welding Seams: Using a hot-air welder, our technicians fuse the membrane seams together, creating a single, watertight layer. This critical step requires skill and precision.

- Flashing Installation: We carefully seal all penetrations—such as pipes, vents, and HVAC units—and the roof perimeter to prevent leaks at these vulnerable points.

- Final Inspection: A comprehensive quality check of all seams, flashing, and terminations is performed to ensure the installation meets manufacturer specifications and our high standards.

Common Mistakes to Avoid During a TPO Roof Replacement

Installation errors can lead to premature roof failure. Avoid these common pitfalls:

- Improper Surface Preparation: Installing over a dirty, wet, or uneven deck will compromise the entire system.

- Incorrect Fastening: Using the wrong fasteners or incorrect spacing can lead to wind uplift.

- Poor Seam Welding: Inexperienced installers can create “cold welds” that look sealed but will separate over time, causing leaks. Proper technique is essential, as noted by manufacturers like GAF.

- Neglecting Flashing Details: Most leaks originate from poorly installed flashing around penetrations.

- Hiring an Unqualified Contractor: TPO installation is a specialized trade. Always choose a certified, experienced contractor to protect your investment.

Maximizing Your Investment: TPO Roof Maintenance

A TPO roof replacement is a major investment; proactive maintenance is key to ensuring it lasts 20-30 years. A few simple practices can prevent costly repairs and protect your warranty.

Essential Maintenance Practices

- Schedule Biannual Inspections: Professional inspections in the spring and fall (and after major storms) catch minor issues before they escalate. Many warranties require them.

- Keep the Roof Clean: Regularly remove leaves, branches, and debris that can clog drains and trap moisture against the membrane.

- Ensure Proper Drainage: Check that gutters, scuppers, and drains are clear. Ponding water—water that remains for over 48 hours—accelerates aging and can void your warranty.

- Inspect Seams and Flashing: Pay close attention to heat-welded seams and the flashing around all penetrations, as these are the most common areas for potential issues.

- Address Damage Promptly: Repair small punctures or tears immediately to prevent water from saturating the insulation and damaging the roof deck.

Is TPO a Good Choice for Delaware’s Climate?

Yes, TPO roofing is an excellent choice for Delaware’s climate. Here’s why:

- Heat and UV Resistance: TPO’s white reflective surface excels in our hot, humid summers by reflecting solar heat, keeping buildings cooler and lowering A/C costs. Some clients report cooling cost reductions of 20-30% after switching from a dark roof.

- Flexibility: The material is designed to expand and contract with Delaware’s temperature swings, resisting the cracks that can plague more rigid roofing systems.

- Storm and Wind Resistance: The strong, heat-welded seams provide superior resistance to wind uplift during coastal storms and nor’easters. We’ve installed TPO systems in high-wind areas like Rehoboth Beach with consistent, proven success.

- Moisture Protection: The monolithic, waterproof surface effectively channels away heavy rain, preventing leaks even during severe downpours.

From Dover to Milford and across Sussex County, TPO delivers reliable, long-lasting performance perfectly suited to our region.

Frequently Asked Questions about TPO Roofing

Here are answers to the most common questions we receive about TPO roof replacement.

How thick should my TPO membrane be?

TPO membranes come in standard thicknesses of 45 mil, 60 mil, and 90 mil. The best choice depends on your specific needs. While 45 mil is sufficient for many applications, 60 mil offers a great balance of durability and cost. Thicker 90 mil membranes are best for roofs with heavy foot traffic or a high risk of punctures. However, manufacturer quality is more important than thickness alone; a high-quality 45 mil membrane will outperform a poorly made 90 mil product.

Can TPO be installed over an existing roof?

Yes, but only under specific conditions. This process, called a “recover,” is possible if the existing roof is a single layer, structurally sound, and completely dry. Delaware building codes typically limit roofs to two layers total. Installing TPO over wet insulation is a critical mistake, as it traps moisture and leads to rot, mold, and premature failure of the new roof. A thorough inspection is required to determine if a recover is a viable option.

How much does a TPO roof replacement cost?

The national average cost for a TPO roof replacement is $4 to $16 per square foot. Most projects in Delaware fall between $4.50 and $10 per square foot. The final price depends on several factors:

- Roof Size and Complexity: Smaller, more intricate roofs with many penetrations cost more per square foot.

- Installation Method: Fully adhered systems are typically more expensive than mechanically fastened ones.

- Insulation: The type and thickness of insulation needed to meet energy codes will affect the cost.

- Tear-Off: If the old roof must be removed, expect to add $1 to $2 per square foot for labor and disposal.

For a personalized quote, check our Roof Replacement Cost Guide 2025 or call us at (302) 222-4065 for a free inspection and estimate.

Conclusion

Choosing a TPO roof replacement is a smart decision for protecting your Delaware property. Its heat-welded seams provide a durable, watertight barrier, while its reflective surface lowers energy costs and stands up to our coastal weather. TPO offers a powerful combination of performance, efficiency, and long-term value.

However, the best materials only perform as well as they are installed. With over 20 years of experience installing TPO roofs across Delaware, First State Roofing & Exteriors has the local knowledge and technical expertise to ensure your project is done right. We are committed to protecting your building with an installation that honors your trust in us.

Your roof is too important to leave to chance. For a professional evaluation and a free, no-obligation estimate for your Roof Replacement project, call us today at (302) 222-4065 to schedule a free inspection.