Why Commercial Roofs Demand Advanced Waterproofing Protection

Effective roof waterproofing solutions are not just a repair measure but a crucial preventative strategy to protect your commercial building’s structural integrity and value. For business owners, understanding these options is key to avoiding costly water damage and ensuring long-term durability, a specialty of expert Delaware roofing contractors. Whether you’re dealing with a flat roof, green roof, or aging system, the right waterproofing approach safeguards your investment and extends your roof’s lifespan.

Top Commercial Roof Waterproofing Solutions:

- Liquid-Applied Membranes – Seamless, flexible coatings (polyurethane, silicone, acrylic) ideal for complex roof shapes.

- Sheet Membranes – Prefabricated TPO, PVC, or EPDM rubber with uniform thickness and high durability.

- Bituminous Systems – Modified bitumen or hot-rubberized asphalt for proven, multi-ply protection.

- Hybrid Systems – Combined technologies for specific challenges like green roofs or high-traffic areas.

Your commercial property represents a significant investment, and water intrusion is one of the most destructive threats to that asset. Industry data shows that waterproofing systems designed for commercial applications can last 10 to 30+ years when properly installed and maintained. Yet many business owners only think about waterproofing after a leak appears—often when damage to insulation, structure, or interior finishes has already occurred.

Commercial roofs face constant exposure to Delaware’s weather extremes, from heavy rainfall and snow to intense summer heat and UV radiation. Flat and low-slope roofs are particularly vulnerable to ponding water, while roof penetrations (HVAC units, vents, drains) create natural weak points. Without robust waterproofing, even minor issues can escalate into mold growth, compromised structural integrity, and business disruptions. Professional roofing services for commercial buildings address these challenges through systematic waterproofing strategies custom to your roof type, existing conditions, and long-term goals.

Why Your Commercial Building Needs Robust Roof Waterproofing

Your commercial building’s roof isn’t just a cover—it’s a sophisticated defense system protecting everything beneath it. When water breaches this barrier, the damage extends far beyond a few ceiling stains. You’re looking at compromised structural integrity, ruined inventory, health hazards, and thousands in emergency repairs. This is why robust roof waterproofing solutions aren’t optional upgrades; they’re essential investments in your property’s longevity and your business’s continuity.

For commercial property owners across Delaware, understanding what makes waterproofing so critical—and what causes it to fail—is the first step toward protecting your investment from costly water intrusion.

The Primary Functions of Waterproofing

At its core, waterproofing creates an impermeable shield that keeps water out of your building envelope, delivering a cascade of protective benefits that directly impact your bottom line.

- Protecting Assets: Water damage can destroy inventory, ruin equipment, and wreck interior finishes, potentially forcing a business closure.

- Preventing Mold Growth: A properly waterproofed roof eliminates the damp conditions that allow mold to thrive, preventing health risks and expensive remediation.

- Maintaining Insulation Effectiveness: Wet insulation loses its thermal resistance (R-value), causing your HVAC system to work harder and increasing costs. Waterproofing keeps insulation dry and your building’s energy efficiency high.

- Shielding the Building Envelope: Waterproofing is the first line of defense, preventing water from migrating into walls and foundations and causing long-term deterioration.

- Ensuring Operational Continuity: A leaky roof disrupts business, creates unsafe conditions, and forces closures. Reliable waterproofing means your business keeps running smoothly.

Common Causes of Roof Leaks and Water Damage

Understanding why commercial roofs leak helps you prevent problems before they start. Flat and low-slope roofs face several specific vulnerabilities.

- Ponding Water: Any area on a flat roof where water collects for more than 48 hours accelerates material degradation and stresses seams.

- Damaged Flashing: Flashing seals vulnerable spots around vents, skylights, and HVAC units. When it cracks or lifts, it creates a direct path for water.

- Material Degradation: UV radiation, temperature extremes, and pollutants cause roofing materials to crack, blister, or shrink over time, diminishing their waterproofing capabilities.

- Clogged Drains and Gutters: Debris blocks drainage systems, causing water to back up and potentially overflow into the building.

- Seam Failure: On membrane roofs, seams are a common weak point. If they separate due to poor installation or age, they become direct entry points for water.

- Severe Weather Damage: Heavy rain, snow, high winds, and hail can tear membranes and compromise the entire system. For guidance on weather-related issues, see our Storm Damage Roof Repair Complete Guide.

- Punctures from Foot Traffic: Maintenance crews, tools, and equipment can puncture durable membranes without proper walkway protection.

- Poor Initial Installation: Shortcuts during installation, improper substrate preparation, or inadequate adhesion create vulnerabilities that lead to premature failure.

A Deep Dive into Commercial Roof Waterproofing Solutions

When it comes to protecting your commercial property from water damage, choosing the right system makes all the difference. Roof waterproofing solutions aren’t one-size-fits-all; they’re engineered for specific roof types, climates, and building needs. Understanding the main categories helps you make an informed decision that protects your investment for decades.

Liquid-Applied Roof Waterproofing Solutions

Liquid-applied systems create a seamless, flexible shield over your entire roof. These coatings are applied as a liquid and cure into a fully adhered, monolithic membrane that acts as a single, unbroken barrier. Their elasticity allows them to expand and contract with temperature swings without cracking, making them ideal for roofs with complex shapes or numerous penetrations.

- Polyurethane membranes offer impressive tensile strength and abrasion resistance, making them a reliable choice for exposed commercial roofs.

- Silicone systems are exceptionally durable and highly reflective, which can reduce heat absorption and contribute to energy savings.

- Acrylic sealants provide solid moisture protection at a lower initial cost, though they may require more frequent reapplication.

- PMMA (Polymethyl Methacrylate) stands out for its rapid curing time and ability to be applied in colder temperatures, which is useful for detail work.

The application process requires professional expertise. The roof surface must be thoroughly cleaned and repaired before a primer is applied to ensure proper adhesion. Contractors then apply one or more coats of the liquid membrane, allowing for proper curing time between each layer.

| Feature | Liquid-Applied Membranes | Sheet Membranes |

|---|---|---|

| Durability | Good to Excellent (10-25+ years) | Excellent (20-30+ years) |

| Cost | Moderate to High (depending on material & complexity) | Moderate to High (depending on material & installation) |

| Application | Slower (multiple coats, curing times) | Faster (large sheets, fewer seams) |

| Flexibility | High (conforms to complex shapes, seamless) | Moderate (prefabricated, requires seam treatment) |

| Best Use | Complex roofs, many penetrations, roof restoration | Large, open roof areas, new construction |

Sheet Membrane Roof Waterproofing Solutions

For large commercial roofs with simple layouts, sheet membranes offer a proven, efficient solution. These prefabricated rolls have a uniform thickness, providing exceptional puncture resistance and longevity. They are unrolled across the roof and secured, creating a durable protective layer.

- TPO (Thermoplastic Polyolefin) is a popular choice for its reflective white surface, which keeps buildings cooler. Seams are heat-welded to create bonds as strong as the membrane itself.

- PVC (Polyvinyl Chloride) shares TPO’s heat-welded installation but offers superior chemical resistance, making it ideal for restaurants or manufacturing facilities.

- EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber membrane that excels in extreme weather, remaining flexible in cold winters. Seams are typically sealed with specialized tapes or adhesives.

Installation methods vary: membranes can be fully adhered, mechanically fastened, or ballasted. Regardless of the method, proper seam treatment is critical to prevent water intrusion.

Bituminous and Asphalt-Based Systems

Bituminous systems have protected commercial buildings for generations, earning a reputation for durability. These multi-ply systems layer materials to create robust waterproofing.

- Modified Bitumen (Mod-Bit) is an evolution of asphalt roofing, reinforced with polymers for improved performance. SBS (Styrene-Butadiene-Styrene) adds rubber-like elasticity for cold flexibility, while APP (Atactic Polypropylene) resists UV radiation and heat.

- Hot-applied rubberized asphalt, such as Hydrotech Monolithic Membrane 6125®, is a premium system applied as a hot fluid that cures into a thick, seamless, and flexible barrier. Learn more about hot-rubberized asphalt solutions from industry leaders.

- Cold-applied systems use asphalt-based emulsions or mastics that are applied at ambient temperatures, making them a safer option for occupied buildings or repairs.

Matching the System to Your Commercial Roof

The architecture of your roof is the primary factor in determining the most effective waterproofing strategy. Different designs present unique challenges that require specialized solutions. The roof waterproofing solutions that work brilliantly on a sprawling flat warehouse roof might not be ideal for a green roof or a complex roof with multiple levels. Understanding your specific roof type is the foundation for selecting a system that delivers optimal protection and longevity.

Waterproofing for Flat and Low-Slope Roofs

Flat and low-slope roofs are common in Delaware’s commercial landscape, but their minimal pitch makes them prone to ponding water, a major threat to roof integrity. Even a slight depression can allow water to collect, which accelerates the breakdown of roofing materials. Proper drainage, with a slope of at least 1/4″ per foot, is critical.

For these roofs, seamless waterproofing systems offer distinct advantages. Liquid-applied membranes (polyurethane or silicone) eliminate seams, which are common failure points. These coatings conform perfectly to every contour, creating a monolithic barrier. Single-ply membranes like TPO and PVC are also excellent choices for large, open flat roofs. Their heat-welded seams create a watertight surface, and their reflective properties help reduce cooling costs. For roofs with numerous obstructions, liquid membranes are invaluable as they can be applied into intricate spaces, ensuring complete coverage.

Considerations for Green and Cool Roofs

Green and cool roofs are at the forefront of sustainable building design, but they introduce unique waterproofing challenges.

Green roofs feature a layer of living vegetation over a waterproofing membrane. This requires a root-resistant membrane specifically engineered to withstand constant moisture and penetration from plant roots. The system must also support the significant weight of soil, plants, and retained water.

Cool roofs use highly reflective coatings to bounce solar radiation back into the atmosphere, reducing a building’s cooling costs. These coatings are typically liquid-applied membranes—often white acrylic or silicone—with a high Solar Reflectance Index (SRI). A higher SRI means better performance and lower energy bills, contributing to your building’s overall Energy Efficiency goals. Many of these coatings are also low in volatile organic compounds (VOCs), making them an environmentally friendly choice.

Whether you’re considering a green or cool roof, the waterproofing system must integrate seamlessly with all other layers of the roof assembly to ensure long-term performance.

Application and Maintenance for Lasting Protection

Selecting the right roof waterproofing solutions is only half the battle. Professional installation and regular maintenance are what transform a good system into decades of reliable protection for your commercial property. Improper application or neglect can lead to leaks, structural damage, and voided warranties.

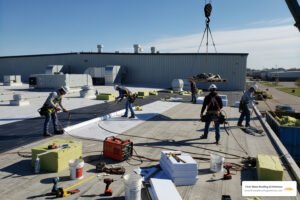

The Professional Application Process

Commercial roof waterproofing is a technical job best left to experienced commercial roofing professionals. The process is systematic to ensure performance from day one.

- Thorough Inspection: The process begins with a detailed examination of the existing roof, substrate condition, drainage, and penetrations to identify hidden problems.

- Substrate Cleaning and Repair: This is a critical step. The surface is cleaned of all dirt, debris, and grease. Any cracks, holes, or deteriorated sections are repaired to create a sound foundation for the new membrane.

- Primer Application: A primer is applied to create a chemical bridge between the old surface and the new waterproofing layer, ensuring strong adhesion.

- Membrane or Coating Installation: For liquid systems, contractors apply each coat at the proper thickness with adequate curing time. For sheet membranes, rolls are positioned with correct overlap, and seams are carefully welded or sealed.

- Detail Work: Special attention is given to flashing around roof penetrations, parapet walls, and expansion joints, as these are where most leaks occur.

- Final Inspection: A final check verifies that every seam is sealed, every detail is addressed, and the entire roof is watertight.

Essential Maintenance Tips

Even the most expertly installed waterproofing system needs ongoing attention to maximize its lifespan. Regular maintenance is the difference between a system that lasts 15 years and one that protects your building for 30 or more.

- Schedule Professional Inspections: Have your roof inspected twice a year, ideally in spring and fall, and after any severe weather events to catch minor issues early.

- Keep Drains Clear: Gutters, downspouts, and roof drains must be kept clear of debris to prevent ponding water, the enemy of any flat roof.

- Address Small Repairs Immediately: A small crack, lifted seam, or worn seal is quick and inexpensive to fix. Left unattended, it can lead to major water intrusion.

- Remove Debris Regularly: Leaves, branches, and trash trap moisture against the membrane and can hide developing problems. Trim overhanging branches to reduce debris.

- Check Seals Around Penetrations: The sealants around HVAC units, vents, and pipes are common leak points and should be checked during each inspection.

Mapei, a leading manufacturer, emphasizes that routine maintenance of drainage systems is essential for the durability of the structure itself. You can explore more technical details in this technical brochure on Roof Waterproofing Systems.

Conclusion

Choosing and implementing the right commercial roof waterproofing solutions is a critical investment in your property’s longevity and safety. From durable sheet membranes on large flat roofs to flexible liquid-applied systems for complex designs, a custom approach ensures maximum protection against water intrusion. For business owners in areas like Dover, DE, partnering with a local expert is key. At First State Roofing & Exteriors, we provide professional assessments and installations to safeguard your commercial investment. Protect your property today by scheduling a free, no-obligation estimate. Call us at (302) 222-4065 for a free inspection.