Why Industrial Roof Repair Demands Immediate Action

A search for industrial roof repair near me is almost always an emergency. When an industrial roof fails, every hour of delay means lost production, damaged inventory, and escalating repair costs. For facility managers in Delaware, acting fast and contacting a trusted Delaware-based roofing contractor is the first step to mitigating a crisis. A compromised roof isn’t just a maintenance issue; it’s a direct threat to your bottom line.

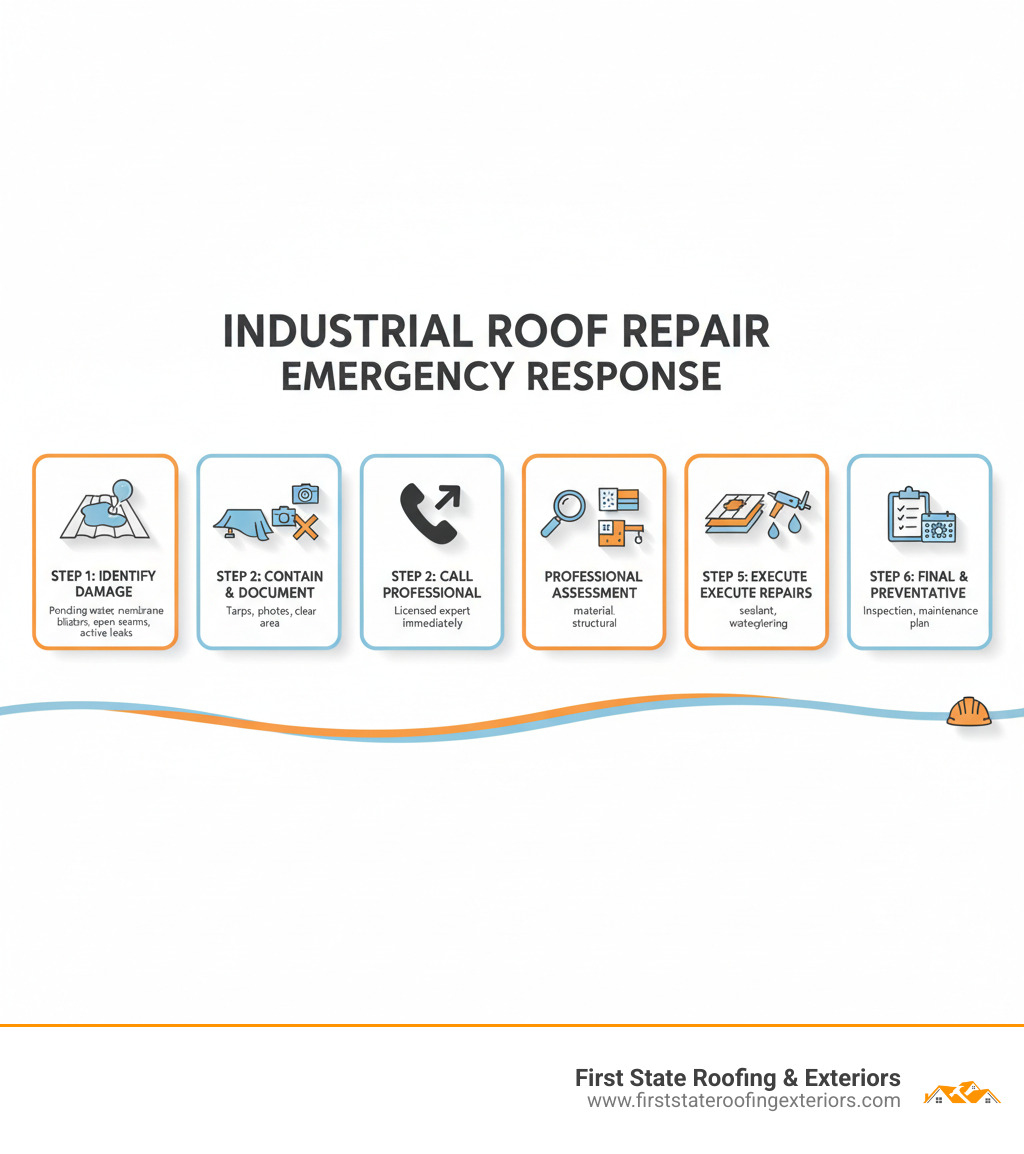

If you have a roof emergency, take these immediate steps:

- Contain: Use buckets and tarps to protect equipment and inventory.

- Document: Take photos and videos of all damage for insurance claims.

- Call: Contact a licensed professional offering 24/7 emergency service.

- Clear: Keep employees and equipment away from leak zones for safety.

- Inspect: Schedule a full assessment to find hidden damage.

Emergency signs that require an immediate call to a professional:

- Active leaks or water intrusion

- Ponding water that doesn’t drain after 48 hours

- Visible punctures, tears, or open seams

- Storm damage, including missing roof sections

- Sagging or visibly compromised structural components

I’m Richard McCain, owner of First State Roofing & Exteriors. For over 20 years, my team has responded to industrial roofing emergencies across Delaware. We understand the unique stresses industrial roofs face—from heavy equipment and chemical exposure to constant foot traffic. This guide provides the knowledge you need to identify warning signs, understand the repair process, and choose a qualified contractor to protect your facility.

If you’re facing roof damage now, call us at (302) 222-4065 for a free inspection and estimate.

Industrial roof repair near me terms to know:

Identifying the Red Flags: When Does Your Industrial Roof Need Repair?

Avoiding catastrophic failures and expensive emergency repairs starts with catching problems early. After two decades of industrial roof repair work in Delaware, I’ve seen how most major roof failures begin as minor, ignored issues. Knowing what to look for is your best defense.

Ponding water: Water that remains on a flat roof for more than 48 hours after rain indicates a drainage failure. The excess weight stresses the structure and accelerates membrane deterioration.

Blistering or bubbling surfaces: These bubbles signal trapped moisture or air beneath the roof membrane. Solar heat causes them to expand and rupture, creating a direct path for water intrusion.

Visible punctures or tears: Dropped tools, foot traffic, or flying debris can create tears in the membrane. A single small puncture can allow significant water entry, often far from the interior leak spot.

Cracked or peeling sealant: The sealant around pipes, vents, and HVAC units degrades from UV exposure. Failed sealant is one of the most common sources of roof leaks.

Damaged flashing: Flashing protects transitions at walls and penetrations. When it cracks, corrodes, or pulls away, it creates an easy entry point for water.

Clogged drains or gutters: Blocked drainage forces water to pool on the roof, leading to leaks and structural stress. Regular cleaning is simple but critical preventative maintenance.

Interior water stains: By the time you see stains on ceilings or walls, water has already breached the roof and saturated insulation, potentially causing structural damage and mold.

Increased energy bills: A sudden spike in utility costs can indicate that water has compromised your roof’s insulation, forcing your HVAC system to work harder.

Loose membrane seams: The seams where roofing sections join are engineered weak points. As the roof ages, thermal expansion and contraction can cause these seams to separate and leak.

Common Causes of Industrial Roof Damage

Understanding the cause helps prevent future issues.

- Weathering and UV Degradation: Sunlight and temperature swings make roofing materials brittle and prone to cracking over time.

- Storm Damage: High winds create uplift forces that tear at seams, while hail can puncture membranes and dent metal panels.

- Foot Traffic: Maintenance crews can inadvertently cause damage by dropping tools or wearing improper footwear on the roof membrane.

- Debris Accumulation: Leaves and trash block drains and trap moisture, accelerating material breakdown.

- Poor Initial Installation: Improperly installed roofs are guaranteed to fail prematurely, regardless of material quality. This is why choosing a certified, experienced contractor is crucial.

- Building Settlement: Gradual shifts in a building’s foundation can stress the roofing system, leading to tears or seam separation.

- Chemical Exposure: For some facilities, corrosive emissions can rapidly degrade roofing materials not designed for chemical resistance.

Catching these red flags early transforms an emergency into planned maintenance. Schedule professional inspections twice a year. Call us at (302) 222-4065 to schedule a free inspection and estimate.

The Industrial Roof Repair Process: A Step-by-Step Guide

When you have a damaged industrial roof, you need a systematic approach that fixes the immediate leak and addresses its root cause. Our industrial roof repair near me process is refined to minimize operational disruption and deliver lasting results.

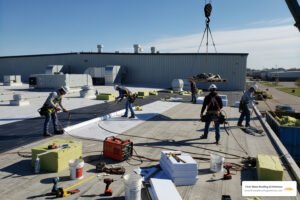

1. Emergency Containment: Our first priority is to stop active leaks. Our team arrives quickly to apply temporary patches or tarps, protecting your equipment and inventory while we assess the situation.

2. Thorough Damage Assessment: We go beyond the obvious damage, inspecting the entire roofing system—membrane, flashing, insulation, and structural deck—to identify all current and potential issues.

3. Professional Leak Detection: Water often travels far from the entry point. We use advanced tools like infrared thermography to pinpoint the exact source of a leak, ensuring we fix the right spot.

4. Material-Specific Repair Plan: A TPO roof requires different repair techniques than a metal or modified bitumen system. We develop a custom plan based on your roof type and budget, explaining your options clearly.

5. Surface Cleaning and Preparation: This step is critical for a durable repair. We carefully clean the area, removing all dirt, debris, and degraded material to ensure a perfect bond for new patches or sealants.

6. Application of Patches, Sealants, or Coatings: Our trained technicians apply reinforced membrane patches, high-performance sealants, or protective coatings, following manufacturer specifications to integrate the repair seamlessly with your existing roof.

7. Waterproofing Reinforcement: We fortify vulnerable areas like seams, penetrations, and roof edges with extra layers of protection to prevent future leaks.

8. Final Quality Inspection: Before leaving, we conduct a rigorous inspection to verify that every repair is watertight and meets our strict quality standards. This ensures your professional roof repair will stand the test of time.

This systematic approach ensures we do the job right the first time. If you’re dealing with roof damage, don’t wait. Call us at (302) 222-4065 for a free, no-obligation inspection and estimate.

Understanding Your Roof: Materials and Their Repair Needs

The material protecting your facility determines its lifespan, common problems, and the correct repair methods. When you search for industrial roof repair near me, a qualified contractor will first ask about your roof type, as each system has unique characteristics. We work with all major different roofing types and understand the specific techniques required for a lasting repair.

| Material Type | Typical Lifespan | Common Issues | Typical Repair Methods |

|---|---|---|---|

| TPO (Thermoplastic Polypropylene) | 15-20 years | Punctures, tears, seam separation, ponding water, UV degradation, shrinkage. | Heat welding, patching with matching TPO material, liquid-applied flashing, seam reinforcement. |

| EPDM (Ethylene Propylene Diene Monomer) | 20-30 years | Punctures, tears, seam separation, shrinkage, hail damage, UV degradation. | Patching with EPDM material, liquid-applied flashing, seam repair with specialized tapes/adhesives, coating for UV protection. |

| Metal Roofing (Standing Seam, Corrugated) | 30-50+ years | Rust, corrosion, loose fasteners, seam separation, hail damage, dents, leaks around penetrations. | Seam sealing, fastener replacement/sealing, panel replacement, coating, flashing repair, caulking. |

| Modified Bitumen (Mod-Bit) | 15-20 years | Cracking, blistering, granule loss, seam separation, tears, delamination. | Patching with matching mod-bit material, heat welding, liquid-applied flashing, coating, re-granulation. |

| Built-Up Roofing (BUR) | 20-30+ years | Cracking, blistering, alligatoring (surface cracking), leaks, ponding water. | Patching with asphalt and felt layers, flood coating with asphalt/gravel, localized membrane replacement, coating. |

| Spray Polyurethane Foam (SPF) | 10-20 years (with coating) | Punctures, hail damage, coating degradation, blistering, delamination. | Foam repair (re-spraying foam), re-coating with elastomeric coatings, patching. |

TPO and PVC Single-Ply Membranes: These flexible, energy-efficient materials are common on modern industrial buildings. Their primary vulnerabilities are punctures and seam separation. We repair them using professional heat-welding techniques to create a seamless, permanent bond.

EPDM Rubber Roofing: Known for its durability, EPDM can last 30 years but is susceptible to punctures and seam failure over time. Repairs involve specialized tapes, adhesives, and liquid-applied flashing that bond permanently to the rubber surface.

Metal Roofing Systems: While extremely durable with a lifespan of 50+ years, metal roofs require maintenance. Common issues include loose fasteners, separating seams, and rust. We address these by sealing seams, replacing fasteners, and applying protective coatings.

Modified Bitumen (Mod-Bit): This multi-layer system is tough but can crack or blister from UV exposure. We repair mod-bit using heat-welding techniques and apply protective coatings to shield it from further sun damage.

Built-Up Roofing (BUR): A traditional multi-layer asphalt and felt system, BUR is robust but can develop surface cracking (“alligatoring”) and blisters with age. Repairs often involve patching with new layers or applying a flood coat to seal the entire surface.

Spray Polyurethane Foam (SPF): This seamless, insulating foam is protected by a top coating. Damage usually involves punctures or coating degradation. We repair SPF by patching the foam and re-applying the protective elastomeric coating.

Each material demands specific knowledge and tools. Our experience across all industrial roof types in Delaware ensures we recommend and execute the most effective, long-lasting repair for your facility. Call us at (302) 222-4065 for a free inspection and estimate.

The Critical Choice: Finding a Qualified “Industrial Roof Repair Near Me”

When your roof is failing, the contractor you choose is critical to protecting your business. In the rush of an emergency, it’s tempting to hire the first company you find, but taking the time to vet your options will prevent costly mistakes. At First State Roofing & Exteriors, we’ve seen the consequences of poor contractor choice: shoddy repairs, safety violations, and surprise costs.

Here’s what to look for in a qualified industrial roofing contractor:

- Licensing and Full Insurance: This is non-negotiable. The contractor must be licensed in Delaware and carry both general liability and workers’ compensation insurance. This protects you from liability for accidents or property damage.

- Manufacturer Certifications: Certifications (e.g., GAF Master Elite) indicate that a contractor has received specialized training and meets high standards, often open uping access to better warranties.

- Proven Industrial Experience: Industrial roofs have unique challenges. A residential roofer lacks the specific knowledge and equipment required. Ask for a portfolio of industrial projects and local references.

- Adherence to OSHA Safety Standards: A reputable contractor will have a documented safety program to protect their workers and minimize your liability. Ask about their safety protocols.

- Positive Local Reviews: Check Google reviews and ask for testimonials. Third-party verification services like GuildQuality show a commitment to transparency and customer satisfaction.

- Comprehensive Written Warranties: A reliable contractor provides a clear workmanship warranty on their repairs, in addition to the manufacturer’s material warranty. Get it in writing.

- 24/7 Emergency Availability: Roof emergencies don’t stick to business hours. Ensure your contractor offers 24/7 emergency roof repair with a team ready to respond.

Key Questions to Ask a Potential Contractor

- What is your experience with my specific roof type (TPO, metal, etc.)?

- Can you provide local industrial references I can contact?

- What safety protocols do your crews follow on-site?

- What does your workmanship warranty cover, and for how long?

- How do you handle unforeseen issues finded during the repair?

Understanding the Cost of an industrial roof repair near me

The cost of an industrial roof repair near me is never one-size-fits-all. A credible contractor will always inspect the roof before providing a detailed, itemized estimate. Key factors influencing the final price include:

- Repair Size and Complexity: A small patch costs far less than addressing widespread damage or underlying structural issues.

- Roof Material Type: Some materials require more expensive tools, materials, and specialized labor (e.g., heat-welding TPO).

- Accessibility and Safety: Difficult-to-access roofs that require cranes or extensive fall protection systems will increase labor and equipment costs.

- Emergency vs. Scheduled Repairs: Expect to pay a premium for after-hours or holiday emergency service due to the immediate deployment of crews.

An unusually low bid often signals cut corners. The best value comes from a fair price backed by quality work, proper insurance, and a solid warranty. Call us at (302) 222-4065 to schedule a free inspection and receive a transparent, itemized estimate.

The Long Game: Prevention, Maintenance, and Long-Term Consequences

When it comes to your industrial roof, a long-term strategy is always the smartest one. Investing in prompt repairs and regular maintenance isn’t just about fixing today’s problem—it’s about protecting your business for years to come.

Benefits of Prompt Industrial Roof Repair

Acting quickly on roof issues provides immediate and long-term benefits:

- Cost Savings: Fixing a small leak now prevents catastrophic water damage to insulation, decking, and structural components, saving you from far more expensive repairs later.

- Asset Protection: Prompt repairs protect valuable equipment, raw materials, and finished products from water damage.

- Business Continuity: Minimizing roof issues prevents operational shutdowns, protecting your production schedules and profitability.

- Employee Safety: A well-maintained roof eliminates slip hazards from leaks and prevents structural risks or mold growth.

Consequences of Neglecting Industrial Roof Repairs

Ignoring red flags can lead to devastating outcomes:

- Structural Damage: Chronic water infiltration rots wood, corrodes metal, and compromises your building’s structural integrity.

- Mold and Mildew Growth: Leaks create the perfect environment for mold, which poses health risks to employees and requires costly remediation.

- Premature Roof Replacement: A roof that could have been saved with timely repairs may deteriorate to the point where a full, expensive replacement is the only option.

- Warranty Voidance: Most manufacturer warranties require proof of regular maintenance. Neglect can void your coverage, leaving you responsible for all costs.

Building a Proactive Roof Maintenance Plan

The best defense is a proactive maintenance plan. This extends your roof’s life and prevents costly surprises.

- Scheduled Semi-Annual Inspections: Have a professional inspect your roof every spring and fall to assess weather-related damage.

- Gutter and Drain Cleaning: Ensure water can flow off the roof efficiently to prevent ponding.

- Debris Removal: Regularly clear leaves, branches, and other debris that can block drains and trap moisture.

- Maintain a Roof History Log: Document all inspections and repairs to track your roof’s condition and inform future decisions.

When is a full replacement a better option for an industrial roof repair near me?

Sometimes, a full replacement is more economical than continued repairs. Consider replacement if:

- The roof has reached the end of its expected lifespan.

- Repair costs are approaching 50% of the replacement cost.

- You are dealing with multiple, recurring leaks across the entire roof.

- You want to upgrade to a more energy-efficient or durable roofing system.

We provide honest assessments to help you decide if an industrial roof repair near me is sufficient or if a replacement is the wiser long-term investment.

Frequently Asked Questions about Industrial Roof Repair

We get a lot of questions about industrial roof repair, and we’re happy to answer them. Here are some of the most common inquiries we receive:

How long does a typical industrial roof repair take?

The timeline for an industrial roof repair depends on the damage. A minor patch may take a few hours, while extensive membrane or flashing repairs could take several days. The material type, weather, and roof complexity are all factors. After a full assessment, we provide a clear project schedule.

Can my business remain open during the roof repair?

Yes, in most cases your business can continue to operate. Professional roofing crews are experienced in working on active industrial sites. We minimize disruption by sectioning off work areas, implementing strict safety protocols, and coordinating closely with your facility management to ensure operations proceed with minimal impact.

What kind of warranty should I expect for an industrial roof repair?

A reputable contractor will provide a workmanship warranty that covers the quality of their repair work, typically for 1 to 5 years. This warranty ensures the repair itself is free from defects caused by faulty application. This is separate from the manufacturer’s material warranty, which covers defects in the roofing products themselves. Always get your warranties in writing.

Conclusion

Protecting your industrial facility starts from the top down. Ignoring roof damage is a gamble that can lead to catastrophic losses in time, money, and operational capacity. By understanding the signs of failure, the repair process, and how to choose a qualified partner, you can make informed decisions that safeguard your investment. As a family-owned, Delaware-based company, First State Roofing & Exteriors specializes in providing prompt, reliable industrial and commercial roofing solutions. Don’t wait for a small leak to become a major disaster. Call us today at (302) 222-4065 for a free inspection and estimate.